ESBE’S ANTI-FREEZE VALVE PROTECTS YOUR HEAT PUMP!

2025-09-23

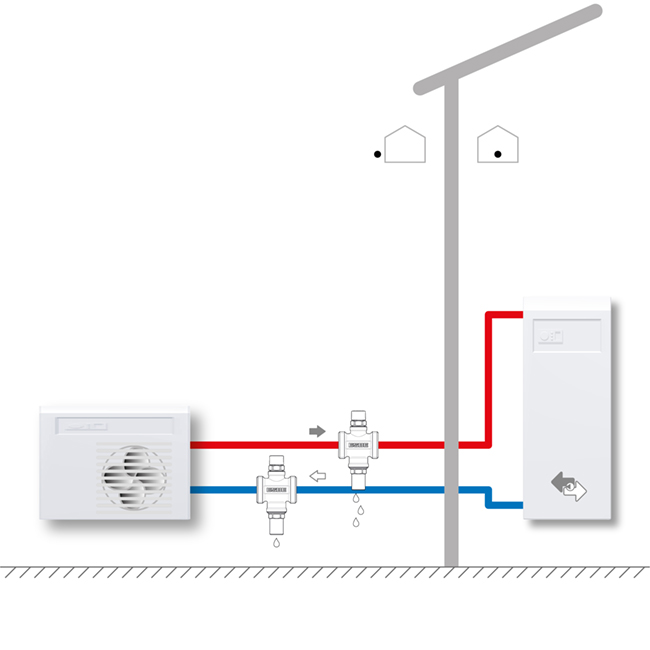

Installation of monoblock heat pumps is popular thanks to their smooth installation. But because a part of the system is placed outdoors, it is vulnerable to freezing, which can lead to costly repairs.

- We have listened carefully to our customers and partners around Europe who have requested an anti-freeze valve in our product range. With our anti-freeze valve, the VTN102 series, we can now offer a solution that perfectly complements our other products and provides increased operational reliability, says PerJohan Brodén, Product Manager.

Protection that works when it’s needed

● Anti-freeze valves are placed in the system’s water flow and monitor the water temperature inside the pipes. When the fluid temperature drops below 3°C, the valve starts to release water, allowing warmer water to reach the valve.

● The valve has a design that prevents the risk of it getting stuck or starting to leak, which means the valve does not require any maintenance to function when needed.

● When the temperature in the fluid rises to 4°C, the valve closes again, and drainage stops. This prevents the system from draining uncontrollably, but guarantees that the water does not freeze.

● The integrated vacuum valve ensures that all water can be drained out if needed. When the temperature rises again, the valve closes, and no manual reset is needed.

What are the benefits of using an anti-freeze valve, for example, to avoid the use of anti-freeze fluids and to protect components from frost damage?

- Anti-freeze fluids provide poorer heat transfer, which in turn reduces the total efficiency of the system, explains Dan Bengtsson, Development Engineer at ESBE.

What are the critical installation and maintenance requirements to ensure that an anti-freeze valve functions optimally and is reliable during cold periods?

- It is crucial that the anti-freeze valve is installed on both the supply and return lines. For the entire system—including the heat pump's outdoor unit—to be able to drain water in the event of a freezing risk, there must be a drainage point on both sides of the pipe system. If you only drain one side, there is a risk that water remains on the other side and freezes.

To ensure that all water drains out of the pipes and pump, the anti-freeze valve must be placed as low as possible. If it is placed higher up, there will be a pocket of water left that can freeze.

It should also be mounted in a location where the risk of freezing is greatest because the anti-freeze valve will be activated when the temperature drops sufficiently. By placing it in the coldest part of the installation, you ensure it is triggered at precisely the right time to prevent frost damage.

New Release: ESBE Anti-Freeze Valve VTN100

Uncompromising reliability

What truly distinguishes our valve from the competition is its reliability. We know that valves can cause problems - it’s common for them to get stuck after standing still for a while. But ESBE’s solution has a construction with an axial seal, which means the sealing surfaces are constantly exercised when the heat pump is in operation, which effectively prevents the risk of it getting stuck.

- Our tests show that the VTN100 works when it is really needed. This gives both installers and end-users a security they have not had before in combination with ESBE’s other products.

The launch of the VTN100 is a part of ESBE’s strategy to continue to deliver smart and sustainable solutions that simplify installation and increase operational reliability. The valve, which will begin being delivered during the third quarter of 2025, allows us to offer a more complete solution for the growing market for monoblock heat pumps. The follow-up version, the VTN200, which is intended for combined heating/cooling systems, is already under development.