JONAS GUIDES US THROUGH ESBE ROTARY 4-WAY VALVES

2026-01-13

Different Valve Types for Different Applications.

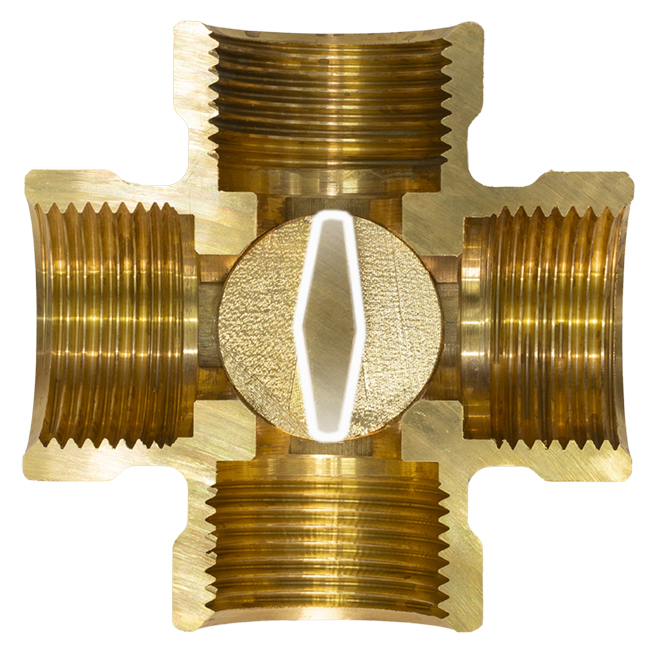

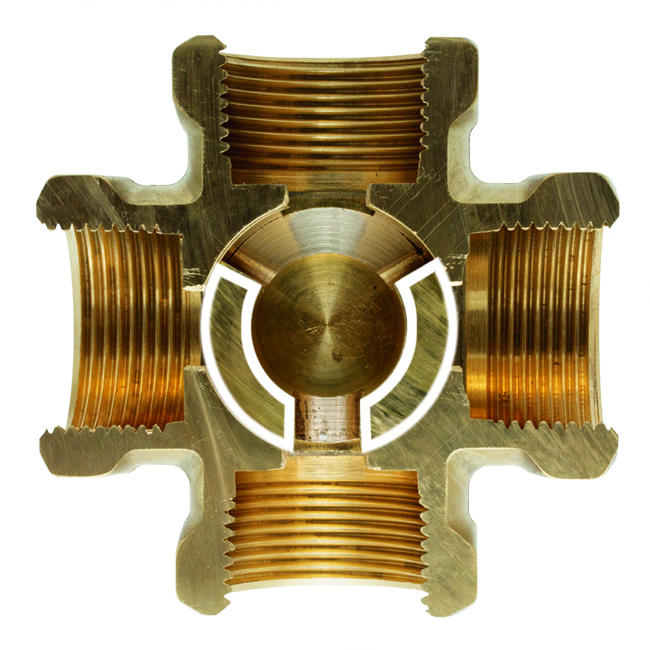

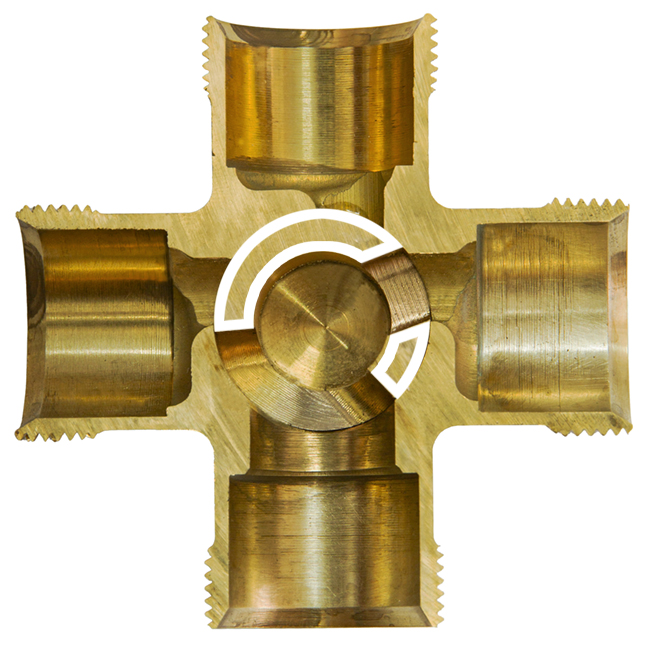

ESBE’s range of rotary 4-way valves (VRx) is made from high-performance brass, ensuring long service life and excellent functionality in both heating and cooling systems. Regardless of which valve you choose, they are all designed to work perfectly with ESBE’s own actuators in the ARA600 series.

But despite these shared features, each series – VRG140, VRB140 and VRB240 – has its own unique function.

The video shows different versions of rotary 4-way valves, which are a crucial component in many modern heating and cooling systems. Jonas takes us through ESBE’s portfolio of 4-way VRx valves and their various applications. 💡

Differences between ESBE 4-way Rotary Valves (VRx)

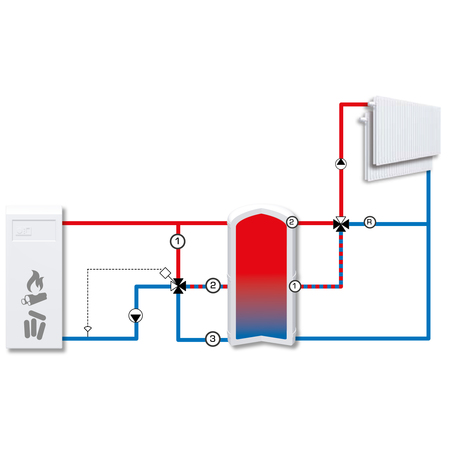

VRG140 with storage tank, mixing

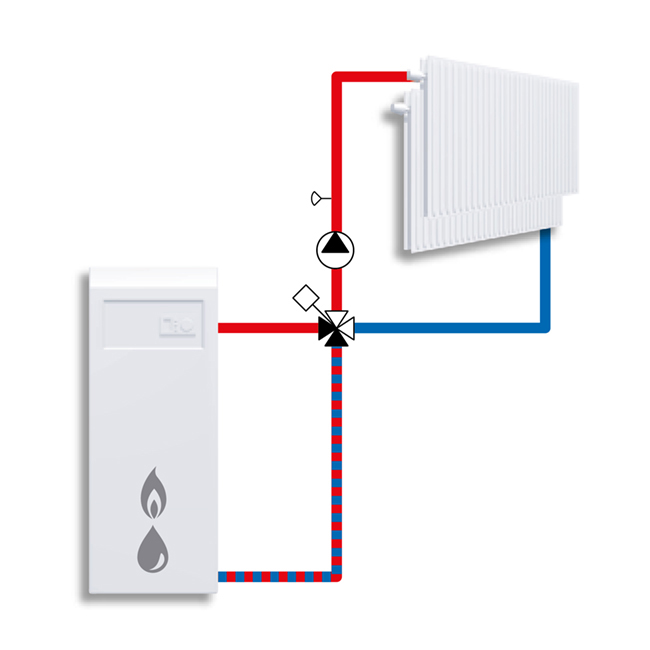

VRG140: return temperature protection via the double mixing principle

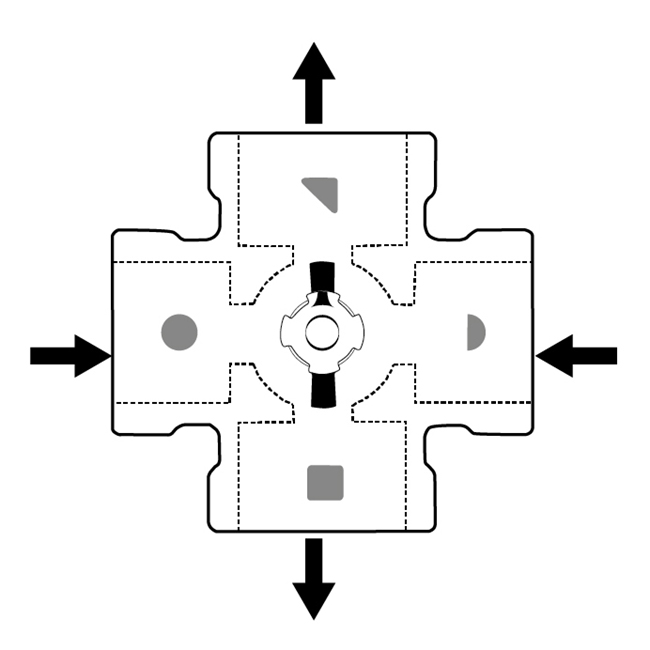

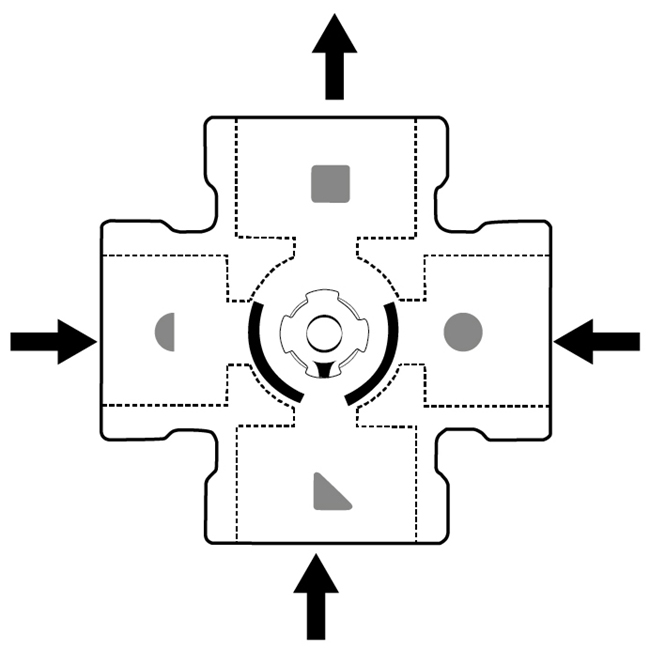

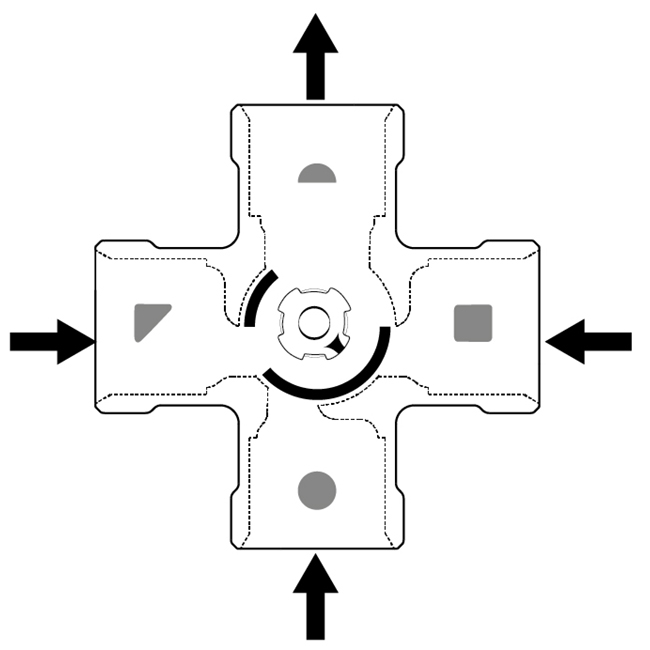

The VRG140 series is mechanically designed so that the internal rotor (plug) controls the flow at four points simultaneously. This double mixing principle ensures that the return temperature remains high while the temperature to the system is optimally regulated.

Jonas explains the benefits:

- What makes the VRG140 series so versatile is its ability to optimize the temperature to the system while actively protecting the heat source. By raising the return temperature, you reduce the risk of corrosion and extend the life of your boiler (when its design requires it). It’s a true system saver!

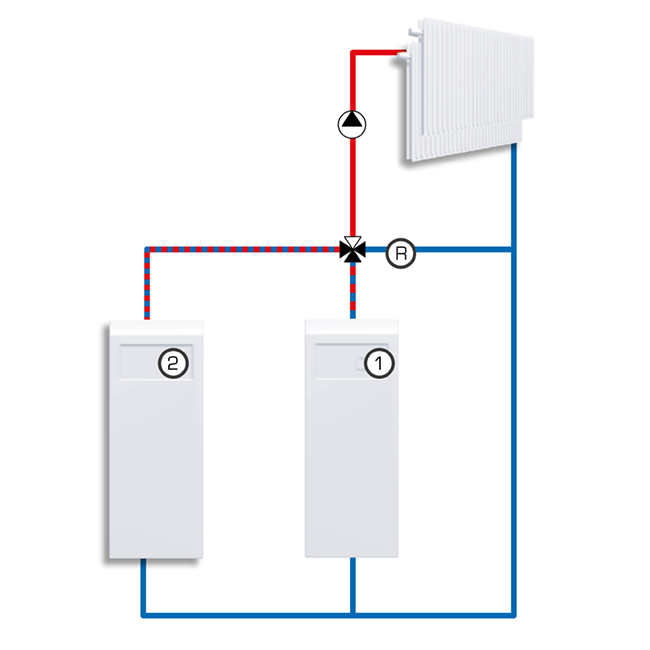

VRB Valves – experts in bivalent applications and diverting

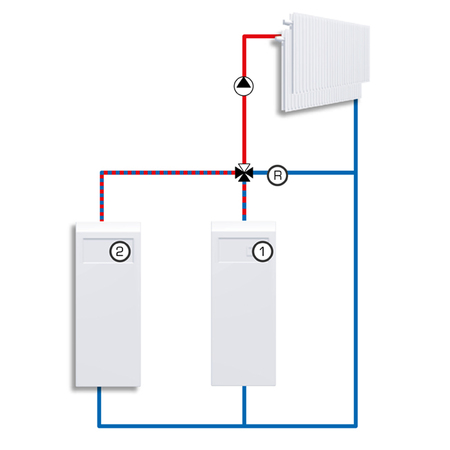

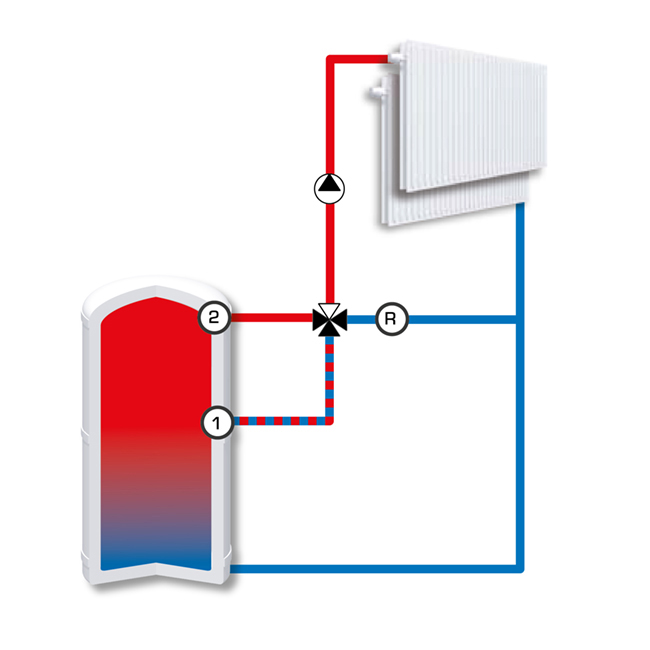

When it comes to the VRB series, the focus is on bivalent applications. Jonas highlights the strength of this series:

- The VRB series is specially designed to handle parallel heat sources, which in practice means it can smoothly switch flow between Heat Source 1 and Heat Source 2. VRB valves are also excellent for diverting applications, where the flow needs to be sent to one of two (or three) separate circuits instead of being mixed.

VRB140 with parallel heat sources

Size, connection and port design

VRB140 with storage tank, mixing

Jonas further explains

- VRB140 and VRB240 are both designed for operation with two parallel heat sources (two levels in a storage tank). However, they differ in size, connection flexibility and port positioning. These differences determine which valve is best suited for your heating system.

VRB140 series is adaptable and powerful. It is available in dimensions DN20 to DN50 and comes with several connection types to ensure broad compatibility in many different systems..

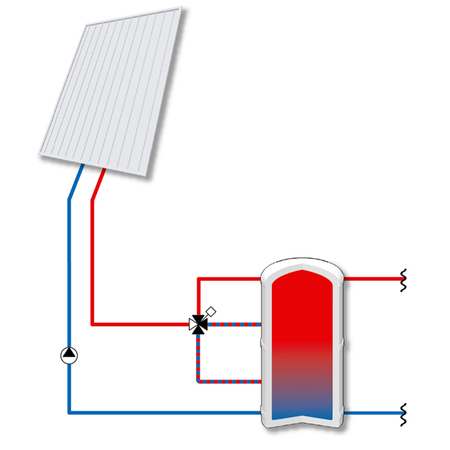

Do you have a solar heating system?

Then you can make the most of every ray of sunshine, says Jonas with a smile:

- The VRB140 valve is a key component for achieving high efficiency in all storage tank systems. When used in solar heating installations, the VRB140 ensures optimal flow control, which is crucial for maximizing solar energy utilization.

The valve’s control contributes to perfect thermal stratification in the tank – hottest at the top, coolest at the bottom. Combined with smart placement of any auxiliary heat (such as electric heaters controlled by the extra switch function in the ARA actuator series), this guarantees maximum system efficiency and reliable heat supply.

VRB140 with solar energy source

Jonas’ Tips for Wood-Fired Systems!

- Burn less, enjoy more.

The heart of the VRB140’s function for wood (and pellet) burners is its ability to create perfect thermal stratification in the storage tank. The valve optimizes flow to preserve the hot layer as much as possible, meaning the boiler’s energy is stored separately and efficiently without mixing. Since the heat remains optimally layered and stored for as long as possible, you can relax – the system makes the most of every log. In short: You won’t need to throw in wood as often!

VRB140 in a solid-fuel system

(Left: Charging the storage tank Right: Mixing in the storage tank)

VRB240 with parallel heat sources

The VRB240 series is available in DN20 and equipped with specific compression fittings for easier installation. Although not noticeably smaller than other models, the VRB240 has a unique feature: it is designed as a direct replacement for our older BIV valve.

Jonas emphasizes how the VRB240’s unique port spacing matches the discontinued BIV valve exactly, enabling quick and easy replacement without modifying the piping. This makes it the obvious choice when upgrading or servicing older installations that previously used BIV.

So, if I have two parallel heat sources or need a pure diverting function, should I look at the VRB series? And if I want optimal mixing and return temperature protection (according to the double mixing principle) in a standard heating system, is VRG140 the right choice?

- Exactly! You’ve got it. The key lies in the application: VRG140 for double mixing and heat source protection/return temperature protection, and VRB for bivalent operation and flow diverting.

Thanks, Jonas, for helping us clarify the differences!

- My pleasure! Choosing the right valve in the right place saves energy, time and hassle. Watch the video too, and you’ll be an expert on this!

Jonas Davidsson