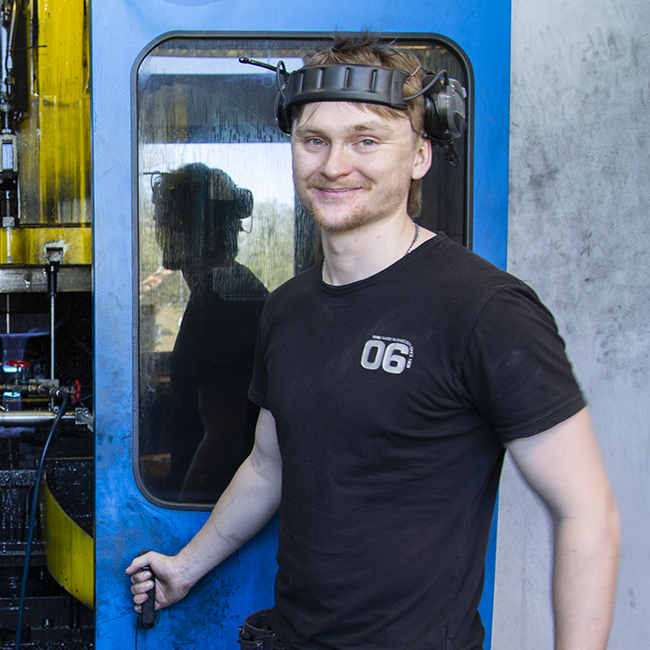

COMPETENCE AND CAMARADERIE IN ESBE'S HOT FORGING DEPARTMENT

2025-05-06

What does a typical workday look like in the hot forging department?

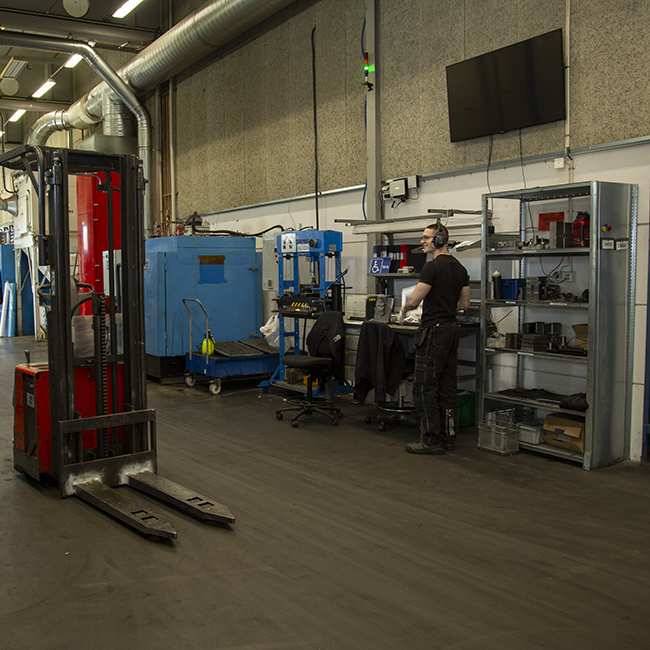

- We usually operate all the machines, but if we're between orders, we tool the machines and prepare for the next manufacturing order. It's often busy, there's always some machine that needs material or service, Axel explains.

Which machines do you use and what do they do?

- We use a cut-off saw to cut the brass, a graphite coating machine that applies a layer of graphite to the pieces so they flow better in the dies, a propane furnace that heats up the pieces to the correct temperature and also feeds the pieces to the hot forging press, a hot forging press that presses the pieces, a trimming press that removes the excess material (flash), and a blasting machine that blasts the pieces and gives them a fine surface, says Vasse.

What exactly is hot forging?

We heat brass pieces to about 800 degrees Celsius and press them between two tools so that they are shaped. It's a process that requires precision, knowledge, and a lot of patience. The material used is brass, chosen for its corrosion resistance and castability; it's also a strong material that doesn't break easily. Additionally, brass can withstand different temperatures, which is important for ESBE valves to function well in both hot and cold water.

The hot forging process itself hasn't changed much during the years the guys have worked in the department. Some machines are faster, the working methods for certain steps have been streamlined, and, for example, there are plans to replace the trimming press.

Challenges and safety in focus

The work is not without its challenges. The heat, especially during the summer, can be intense.

- We drink a lot of water and try to get as much fresh air as possible, says Vasse.

Safety is always the highest priority. There is always a risk of burns, so you have to be careful and know what you're doing. It's also very dusty at some of the stations, accordingly, the required protective equipment is essential!

- An accident can lead to serious injuries; we use protective equipment and common sense, emphasizes Vasse. - We also try to think about how we can improve the environment to make it safer and smoother to work in, Axel explains.

To get an insight into their innovative ideas, even those that may not be feasible, we ask: What's the craziest idea you've had to improve the hot forging process, even if it was unrealistic?

- To replace all the machines with ONE machine that does ALL the steps, laughs Vasse.

When we interview the guys, we have to step out of the hot forging department. The noise is loud and intense. They wear headphones with hearing protection and communication so they can both make calls and talk to each other without having to take them off. With all this racket, the headphones serve not only as a way to communicate, but are also vital for their well-being and productivity.

When asked what makes them proud of their work, they answer:

- That we are an important part of the process. Knowing that what we do is of high quality and that we take responsibility for our work. Yes, and seeing how our work contributes to the whole.

When the machines fall silent and the workday is over, Vasse and Axel gladly exchange the noise for the sound of computer games or laughter with friends and family.

- It's great that we get along so well, but we don't really hang out much outside of work. However, Vasse has got me to start working out at ESBE's gym, so we spend some time there together, says Axel with a smile.

Tight team

If Axel quits, Vasse quits; if Vasse quits, Axel quits. After 4 years (Axel) and 6 years (Vasse), they are a very tight team in the Hot Forging Department. "We're a package deal!" When we check with their team leader, Christoffer Liljeblad, about this, he laughs and says:

- With those guys, you get a 2-for-1 deal!

Vasse has a clear vision of one day starting his own business, while Axel takes life a little more as it comes. But on one point, they completely agree: the best thing about working right here is undoubtedly the COLLEAGUE.

Their tips for anyone curious about hot forging are straightforward:

- In the hot forging department at ESBE, you have to be okay with a bit of dirt, and be prepared for some noise and heat. It's also an advantage to be a quick-thinking problem solver!

In Vasse and Axel, the hot forging department has two young, driven guys who not only know how to handle the machines but also how to create a good atmosphere at work. But when we ask if they can share a funny memory from work, they laugh and say they have many – but none they can share... Hm? 😊

Related links

ESBE Ambassadors

From rod to finished product